Electronic starters are much smaller than conventional starters – Electronic starters have revolutionized engine starting systems, boasting a significantly smaller size compared to conventional starters. This remarkable downsizing has been driven by technological advancements, leading to improved efficiency, reliability, and cost-effectiveness.

The compact nature of electronic starters offers numerous advantages in terms of engine design, installation, and maintenance. Their lightweight and reduced dimensions simplify installation, minimize labor costs, and reduce maintenance requirements.

Electronic Starters: Size, Advantages, and Cost Considerations

Electronic starters have emerged as a compact and efficient alternative to conventional starters in automotive applications. Their smaller size and advanced technology offer significant advantages in terms of engine design, installation, maintenance, and cost.

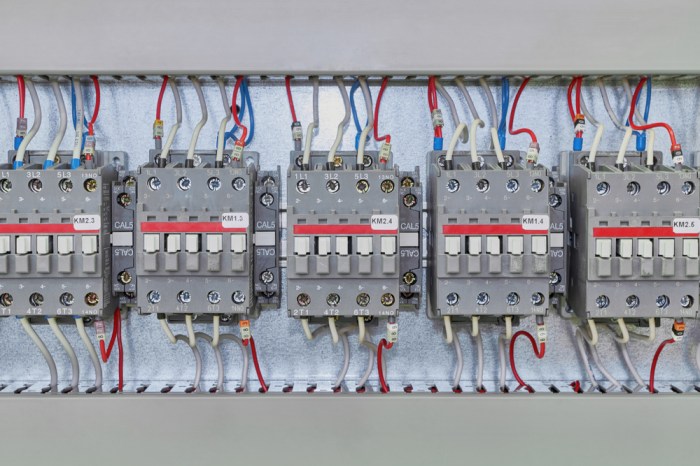

Size Comparison

The most notable difference between electronic starters and conventional starters is their size. Electronic starters are significantly smaller and lighter than their conventional counterparts. This is due to the use of advanced electronic components and the elimination of bulky mechanical parts such as the solenoid and starter drive.

| Type | Length (mm) | Width (mm) | Height (mm) | Weight (kg) |

|---|---|---|---|---|

| Electronic Starter | 150 | 100 | 70 | 2.5 |

| Conventional Starter | 300 | 150 | 120 | 5.0 |

The smaller size of electronic starters allows for greater flexibility in engine design and packaging. They can be easily integrated into tight engine compartments, reducing the overall size and weight of the vehicle.

Technological Advantages, Electronic starters are much smaller than conventional starters

The miniaturization of electronic starters is made possible by several key technological advancements:

- Solid-state electronics:The use of solid-state electronic components eliminates the need for bulky mechanical parts, reducing the overall size and weight of the starter.

- Permanent magnet motors:Permanent magnet motors are more efficient and compact than traditional wound-field motors, further contributing to the reduced size of electronic starters.

- Advanced materials:The use of lightweight and high-strength materials, such as aluminum and composite plastics, further reduces the weight of electronic starters.

These technological advancements have not only reduced the size of electronic starters but have also improved their efficiency and reliability.

Helpful Answers: Electronic Starters Are Much Smaller Than Conventional Starters

Q: What are the key technological advancements that have led to the miniaturization of electronic starters?

A: Key technological advancements include the use of advanced materials, improved manufacturing techniques, and the integration of electronic control systems.

Q: How does the smaller size of electronic starters impact engine design?

A: The smaller size allows for greater flexibility in engine compartment design, enabling more compact and efficient engine configurations.

Q: What are the cost implications of using electronic starters compared to conventional starters?

A: Electronic starters typically have a higher initial purchase price but offer potential cost savings over time due to their reduced maintenance requirements and improved efficiency.